How to become an industry leader: 10 lessons from 10 years with Hi-Kalibre

IRE specializes in the purchase and supply of products for the international oil and gas industry....

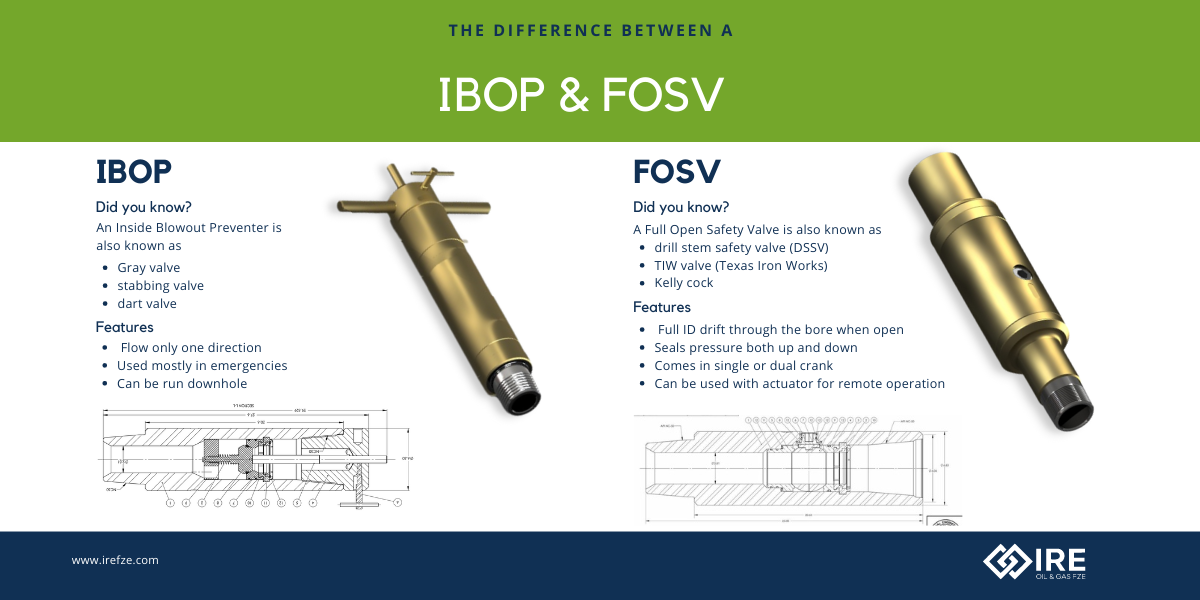

There are two types of stabbing valves that must be prepared for well control. The Full Opening Safety Valve (FOSV) is a ball type valve and the Inside Blowout Preventer Valve (IBOP), which is a plunger style valve.

Stick around to debunk the ins-and-outs of the terminology of these two valves with us.

IBOPs and FOSVs have been used on drilling rigs for 30+ years. These valves are a critical part of drilling operations. Over time, and depending which side of the world you're on, you may have picked up many different names along the way.

We'll break it down.

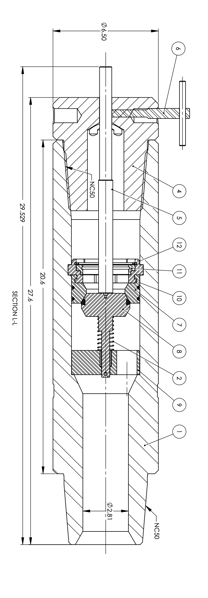

An IBOP or an Inside BOP (Inside Blowout Preventer) is a device that can be installed in the drill string that acts as a check valve allowing drilling fluid to be circulated down the string but prevents back flow.

These high-pressure safety valves and associated equipment are designed to shut off the well hole and prevent the escape of the underground fluids and prevent a blowout from occurring. IBOPs are designed to prevent emergencies. They are typically used as a last attempt to stop pressure from coming up the well.

Inside Blowout Preventers are also known around the world as stabbing valves, dart valves, Gray valves, drop-in valves and heavy-duty check valves.

A stabbing valve is connected to the work string in the event that the well starts to flow when running or retrieving the string and is kept on the rig floor as a contingency against unexpected well flow.

A Gray valve, named after the company that makes it, is a back-pressure type valve (or float valve) that allows stripping operation into the hole without mudflow upward through the valve.

Dart valves refer to the plunger mechanism which is shaped like a dart that is positioned in the drill string to control formation pressure during kicks and controls the back flow through the inside of the drill pipe itself.

The drop in valve or D.I.V. is dropped into the drill string and falls to a special landing sub that is usually located near to the top drill collar in the drill string. It allows the driller to pump

mud down the string but the check valve will not allow influx fluid to flow up the string.

The heavy-duty check valve is a plunger check that crew stab into the drill pipe at the surface, usually used during stripping operations.

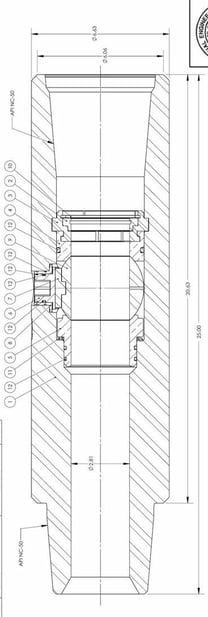

A FOSV (Full Opening Safety Valve) is a ball valve designed to withstand high pressure conditions and is able to hold pressure from both directions. This valve is named “Full Opening” because when the ball valve is opened, the flow path has a smooth, open inside diameter. These valves have several functions depending on type of rig and drilling operation.

The valve should be always located on the rig floor and left in the open position, which is critical so the valve can stabbed quickly into drill string if the well flows through drill pipe.

Full Opening Safety Valves are also known as a drill stem safety valve (DSSV), TIW (Texas Iron Works), top drive IBOP, Kelly valve (upper and lower), mud saver valve, and Kellycock (upper and lower).

Drill String Safety Valves (DSSVs) are used to prevent blowouts through the drill string during tripping operations. DSSV is the preferred term of the brand, Hi Kalibre.

TIW is one of the first companies to make ball type Safety and Kelly valves. TIW Valve (Texas Iron Works) is often used as the generic name for a drill string safety valve.

The upper Kelly valve, or Kellycock, is used on conventional rigs where there is no top drive and installed between the Kelly and the swivel and normally has left-hand threads. The basic purpose of this valve is to isolate the fluid in the drill string from the swivel, rotary hose or standpipe and to prevent leaks or rupture under well conditions. The upper Kelly valve is often opened and closed by a hydraulic or pneumatic actuator that can be separately mounted or attached to the top drive.

A lower Kelly valve, or lower Kellycock, is used on conventional rigs where there is no top drive and is installed on the lower end of the Kelly and used when the upper Kelly valve is damaged or not easily accessible. The lower Kelly valve is often opened and closed by a hydraulic or pneumatic actuator that can be separately mounted or attached to the top drive.

The upper and lower safety valves on top drive systems are connected together. Should a kick occur, the safety valves are immediately connected to the drill string, and the upper valve remotely closed. There is no need to have another safety valve on standby as with Kelly drive operations.

The term was popularized by Tesco corporation in Canada when they supplied their top drives with mud saver valves instead of IBOPs. The mud saver valve closes when circulation is stopped, retaining the mud inside the Kelly or top drive to minimize spillage and mud waste. The main function of the valve is focused on cutting mud flow when making and breaking connections.

The most common manufacturers of the IBOP and FOSV valves are Hi-Kalibre, M&M Oil Tools, M&M International, Packard, Global, ITAG, TIW, and Gray.

An IRE partner for over 10 years, Hi-Kalibre Equipment Ltd., is a Canadian company that specializes in creating and manufacturing Blow Out Prevention equipment for oil & gas exploration worldwide. The Hi-Kalibre team has over 50 years combined experience with many international projects attached to its name.

The Canadian company now enlists a full line of patent protected products revolutionizing the blowout prevention industry. They specialize in manufacturing:

Hopefully one day keeping track of all the unnecessary terminology will lead to an industry standardization of terms. Until then, keep up with IRE for more industry related educational information and news! We've got you covered.

Let us tell you more about our other Partners and Products!

References:

The team at IRE has always felt very fortunate to work with an array of exceptional partners within...

Pulsation dampeners can be used in any industry where fluid flow applications are involved. They...